Protecting workers should be the highest priority for businesses, but recent incidents have shown workplaces overlook potential of injury or death as a result of arc and clothing ignition flashes. Non-compliance with testing and tagging regulation, ineffective control measures, untrained workers, poor repair and maintenance practices, and improper personal protective equipment (PPE) and clothing are all important risk factors that must be addressed and are often overlooked. A recent incident in Western Australia left an electrician with first-degree burns to the head, face and neck. An arc flash and blast occurred as a result of poor workplace procedures, with an investigation finding that many of the risk factors mentioned above had not been addressed. If you are a person conducting a business or undertaking (PCBU), or an interested worker, the following article will discuss flash burns, those at risk, OH&S standards, as well as tips on preventing flash burns.

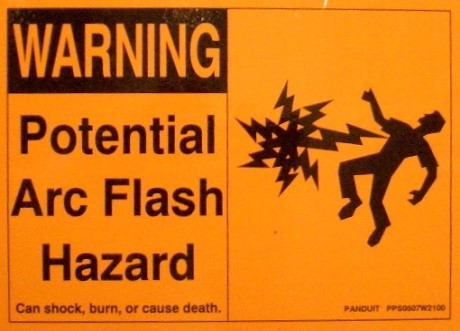

The primary cause of flash burns are risks associated with electrical hazards. When high voltage differences exist across a gap between conductors, this creates a powerful, high-amp current that travels through the air. A rapid release of large amounts of energy follows, which is known as an arc flash or arc blast. These arc flashes have recorded temperatures as high as 20,000 ̊C, and can cause serious injuries or death.

Workers who engage in welding, working hot metals, handling flammable liquids, gases or vapours are exposed to flash ignition and the inevitable risk of serious burns leading to death.

Workers considered at risk are those working in:

A PCBU is responsible for identifying flash risks in the workplace. It is important that the PCBU carries out an effective risk assessment to ensure appropriate control measures are in place. Such control measures should include enforcing PPE requirements, which will be discussed below.

The US standard NFPA 70E is used as a credible guide in Australia. This resource, along with the AS/NZS 4836:2011, are useful for PCBUs looking to maintain electrical safety standards.

The highly regarded NFPA 70E uses two metrics for risk assessment that need explanation:

(cal/cm2) needed to have a 50% risk of inflicting a 2nd or 3rd degree burn. All credible FR Clothing and PPE manufacturers clearly label all FR rated products with a HRC number.

The potential for any flash ignition should be minimised through the risk control processes prescribed by Safe Work Australia, but will always include, elimination or substitution, engineering controls, and administrative controls like training and, of course, training in the selection and maintenance of suitable PPE.

Workers can wear two types of fabric for flash protection. Inherently protected garments may char but will not catch fire, flash or burn over a given service lifetime. Users should be aware that chemically treated garments may use a retardant that washes out over time. Chemically treated garments may prove a suitable option depending on the life cycle of the garment itself . Determining which garment best suits your work environment will depend on a combination of factors, such as the heat potential of the ignition source, and the heat protection calorific value of garments and other PPE, especially face and eye protection (conventional eye and face protection can melt and also offer no intense light and heat protection to the eyes) .

SafetyQuip can offer a range of workwear solutions depending on the application for consideration when protecting workers against flash burn, such as TenCate TecaSafe Plus Workwear. as the inherent protection will never wash or wear out. The following brands are available at SafetyQuip stores and online:

There can be quite job specific risks that have not been identified in a workplace or may not be known or understood in a particular location, industry or nature of work. For this reason it is recommended that an OH&S professional be consulted.

Significant Incident Report – Government of Western Australia, Department of Mines and Petroleum: View PDF

Safety Gear - Workwear - Footwear - Site Safety

Meeting your safety obligations to your workforce is a serious business. Standards evolve, and it can be tough to keep abreast of them. So it’s great to know you have a partner in SafetyQuip – a business that makes it its business to know your safety issues, and stocks all the safety workwear and PPE you will need to address them.

At SafetyQuip, we stock every kind of safety equipment and PPE, including respiratory protection, HI VIS safety workwear, height safety and skin protection. We stock safety equipment for materials handling, with ladders, platforms and elevated work spaces. And we’ve got you covered for personal protective equipment for the feet, with waterproof and steel capped work boots, plus a range of accessories.

Read More